| Photo |

Наименование |

Article |

Цена |

|

|

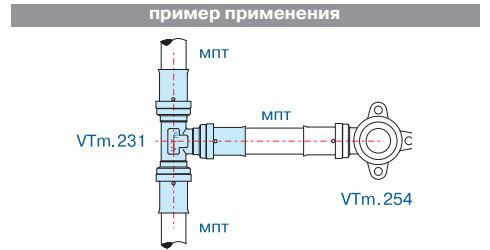

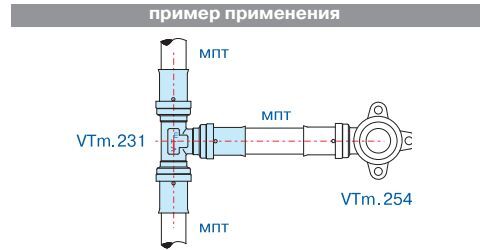

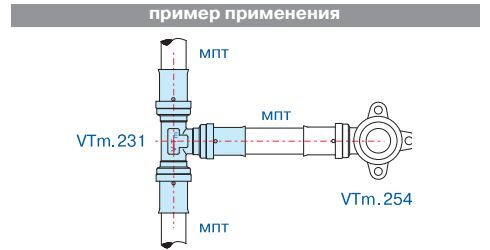

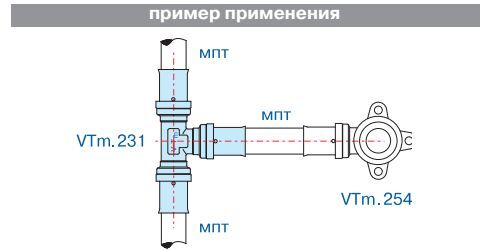

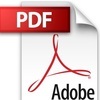

VALTEC T-piece, d - 26 [Code number: VTm.231.N.262626]

Details

|

VTm.231.N.262626 |

919 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 97 |

49 |

26 |

26 |

26 |

0,279 |

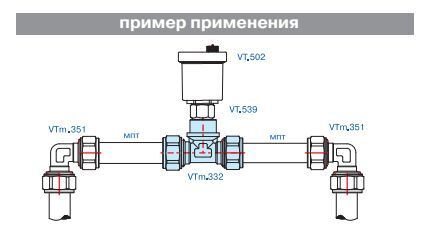

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

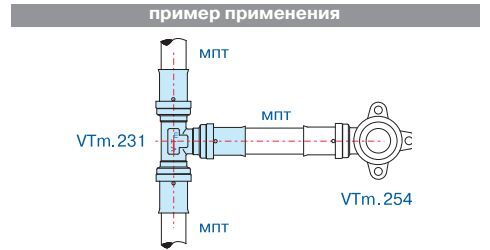

VALTEC T-piece, d - 26х32х26 [Code number: VTm.231.N.263226]

Details

|

VTm.231.N.263226 |

1 564 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 103 |

52 |

26 |

32 |

26 |

0,432 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

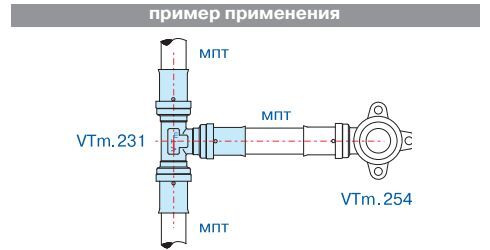

VALTEC T-piece, d - 32х16х32 [Code number: VTm.231.N.321632]

Details

|

VTm.231.N.321632 |

1 548 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 104 |

51 |

32 |

16 |

32 |

0,454 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 32х20х26 [Code number: VTm.231.N.322026]

Details

|

VTm.231.N.322026 |

1 497 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 104 |

51 |

32 |

20 |

26 |

0,397 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 32х20х32 [Code number: VTm.231.N.322032]

Details

|

VTm.231.N.322032 |

1 532 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 104 |

51 |

32 |

20 |

32 |

0,327 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 32х26х26 [Code number: VTm.231.N.322626]

Details

|

VTm.231.N.322626 |

1 458 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 104 |

52 |

32 |

26 |

26 |

0,412 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 32х26х32 [Code number: VTm.231.N.322632]

Details

|

VTm.231.N.322632 |

1 560 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 104 |

52 |

32 |

26 |

32 |

0,334 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 32х32х20 [Code number: VTm.231.N.323220]

Details

|

VTm.231.N.323220 |

1 414 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 103 |

52 |

32 |

32 |

20 |

0,393 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 32х32х26 [Code number: VTm.231.N.323226]

Details

|

VTm.231.N.323226 |

1 584 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 104 |

52 |

32 |

32 |

26 |

0,431 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 32 [Code number: VTm.231.N.323232]

Details

|

VTm.231.N.323232 |

1 570 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 112 |

56 |

32 |

32 |

32 |

0,446 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

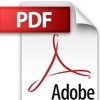

VALTEC T-piece with female thread, d - 16х1/2"х16 [Code number: VTm.232.N.160416]

Details

|

VTm.232.N.160416 |

404 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 84 |

28 |

16 |

16 |

1/2" |

0,120 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece with female thread, d - 20х1/2"х20 [Code number: VTm.232.N.200420]

Details

|

VTm.232.N.200420 |

558 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 88 |

29 |

20 |

20 |

1/2" |

0,128 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece with female thread, d - 20х3/4"х20 [Code number: VTm.232.N.200520]

Details

|

VTm.232.N.200520 |

802 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 90 |

32 |

20 |

20 |

3/4" |

0,158 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece with female thread, d - 26х1/2"х26 [Code number: VTm.232.N.260426]

Details

|

VTm.232.N.260426 |

939 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 97 |

31 |

26 |

26 |

1/2" |

0,208 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece with female thread, d - 26х3/4"х26 [Code number: VTm.232.N.260526]

Details

|

VTm.232.N.260526 |

1 119 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 97 |

34 |

26 |

26 |

3/4" |

0,222 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece with female thread, d - 26х1"х26 [Code number: VTm.232.N.260626]

Details

|

VTm.232.N.260626 |

1 199 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 98 |

37 |

26 |

26 |

1" |

0,252 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece with female thread 32х3/4"х32 [Code number: VTm.232.N.320532]

Details

|

VTm.232.N.320532 |

1 319 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 104 |

39 |

32 |

32 |

3/4" |

0,429 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece with female thread, d - 32х1"х32 [Code number: VTm.232.N.320632]

Details

|

VTm.232.N.320632 |

1 424 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 104 |

39 |

32 |

32 |

1" |

0,444 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece with female thread, d - 32х1 1/4"х32 [Code number: VTm.232.N.320732]

Details

|

VTm.232.N.320732 |

2 075 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 122 |

46 |

32 |

32 |

1 1/4" |

0,480 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece with female thread, d - 40х1"х40 [Code number: VTm.232.N.400640]

Details

|

VTm.232.N.400640 |

2 562 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

G |

Weight |

| mm |

mm |

mm |

mm |

|

kg/pc |

| 124 |

46 |

40 |

40 |

1" |

0,564 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|