| Photo |

Наименование |

Article |

Цена |

|

|

(OUT OF PRODUCTION) - VALTEC (MINKOR) T-piece, pressing connection, d - 16 [Code number: MKm.231.Y.161616]

Details

|

MKm.231.Y.161616 |

|

|

|

|

|

VALTEC (MINKOR) T-piece, pressing connection, d - 20х16х20 [Code number: MKm.231.Y.201620]

Details

|

MKm.231.Y.201620 |

|

|

|

|

|

(OUT OF PRODUCTION) - VALTEC (MINKOR) T-piece, pressing connection, d - 20 [Code number: MKm.231.Y.202020]

Details

|

MKm.231.Y.202020 |

|

|

|

|

|

VALTEC (MINKOR) T-piece, pressing connection, d - 16 [Code number: MKm.331.Y.161616]

Details

|

MKm.331.Y.161616 |

|

|

|

|

|

(OUT OF PRODUCTION) - VALTEC (MINKOR) T-piece, pressing connection, d - 20 [Code number: MKm.331.Y.202020]

Details

|

MKm.331.Y.202020 |

|

|

|

|

|

(OUT OF PRODUCTION) - VALTEC T-piece, pressing connection, with female thread, d - 16х1/2" [Code number: MKm.332.Y.160416]

Details

|

MKm.332.Y.160416 |

|

|

|

|

|

(OUT OF PRODUCTION) - VALTEC T-piece, pressing connection, with male thread, d - 16х1/2" [Code number: MKm.333.Y.160416]

Details

|

MKm.333.Y.160416 |

|

|

|

|

|

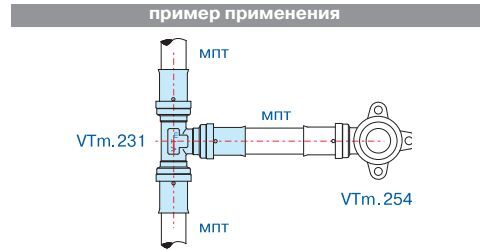

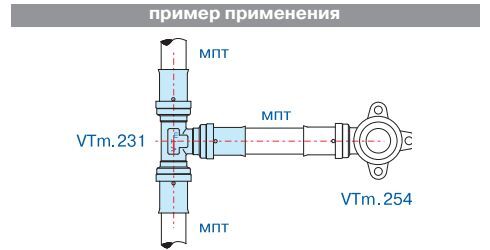

VALTEC T-piece, d - 16 [Code number: VTm.231.N.161616]

Details

|

VTm.231.N.161616 |

390 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 83 |

42 |

16 |

16 |

16 |

0,099 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 16х20х16 [Code number: VTm.231.N.162016]

Details

|

VTm.231.N.162016 |

645 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 88 |

44 |

16 |

20 |

16 |

0,130 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 20х16х16 [Code number: VTm.231.N.201616]

Details

|

VTm.231.N.201616 |

569 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 88 |

44 |

16 |

16 |

20 |

0,126 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 20х16х20 [Code number: VTm.231.N.201620]

Details

|

VTm.231.N.201620 |

588 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 88 |

44 |

20 |

16 |

20 |

0,142 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 20х20х16 [Code number: VTm.231.N.202016]

Details

|

VTm.231.N.202016 |

610 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 88 |

44 |

16 |

20 |

20 |

0,134 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 20 [Code number: VTm.231.N.202020]

Details

|

VTm.231.N.202020 |

568 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 88 |

44 |

20 |

20 |

20 |

0,148 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 20х26х20 [Code number: VTm.231.N.202620]

Details

|

VTm.231.N.202620 |

1 018 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 96 |

49 |

20 |

26 |

20 |

0,258 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 26х16х20 [Code number: VTm.231.N.261620]

Details

|

VTm.231.N.261620 |

927 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 96 |

47 |

26 |

16 |

20 |

0,233 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 26х16х26 [Code number: VTm.231.N.261626]

Details

|

VTm.231.N.261626 |

907 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 97 |

46 |

26 |

16 |

26 |

0,225 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 26х20х16 [Code number: VTm.231.N.262016]

Details

|

VTm.231.N.262016 |

976 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 97 |

48 |

26 |

20 |

16 |

0,231 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 26х20х20 [Code number: VTm.231.N.262020]

Details

|

VTm.231.N.262020 |

1 022 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 97 |

48 |

26 |

20 |

20 |

0,219 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 26х20х26 [Code number: VTm.231.N.262026]

Details

|

VTm.231.N.262026 |

867 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 97 |

48 |

26 |

20 |

26 |

0,237 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC T-piece, d - 26х26х20 [Code number: VTm.231.N.262620]

Details

|

VTm.231.N.262620 |

1 065 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

В |

D1 |

D2 |

D3 |

Weight |

| mm |

mm |

mm |

mm |

mm |

kg/pc |

| 97 |

48 |

26 |

26 |

20 |

0,234 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|