| Photo |

Наименование |

Article |

Цена |

|

|

(OUT OF PRODUCTION) - VALTEC (MINKOR) Coupling, d - 16 [Code number: MKm.203.Y.001616]

Details

|

MKm.203.Y.001616 |

|

|

|

|

|

(OUT OF PRODUCTION) - VALTEC (MINKOR) Coupling, d - 20 [Code number: MKm.203.Y.002020]

Details

|

MKm.203.Y.002020 |

|

|

|

|

|

VALTEC (MINKOR) Coupling, d - 16 [Code number: MKm.303.Y.001616]

Details

|

MKm.303.Y.001616 |

|

|

|

|

|

(OUT OF PRODUCTION) - VALTEC (MINKOR) Coupling, d - 20 [Code number: MKm.303.Y.002020]

Details

|

MKm.303.Y.002020 |

|

|

|

|

|

VALTEC Coupling, d - 16 [Code number: VTm.203.N.001616]

Details

|

VTm.203.N.001616 |

206 rub |

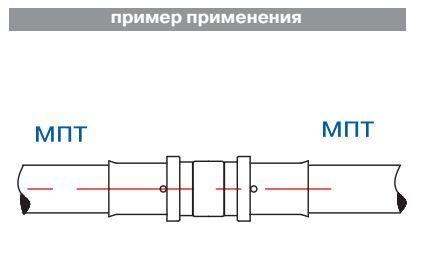

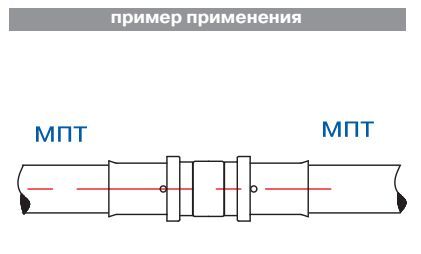

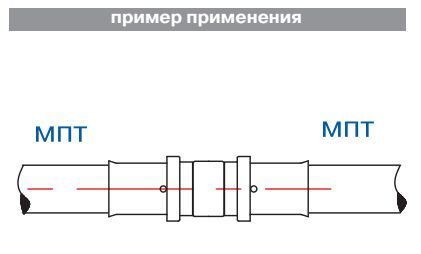

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 60 |

16 |

16 |

0,039 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 20х16 [Code number: VTm.203.N.002016]

Details

|

VTm.203.N.002016 |

285 rub |

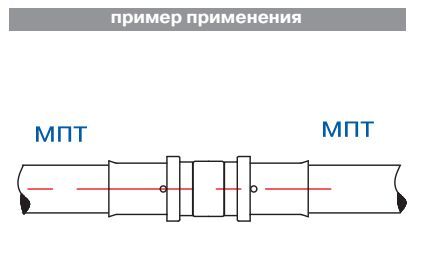

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 60 |

20 |

16 |

0,063 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 20 [Code number: VTm.203.N.002020]

Details

|

VTm.203.N.002020 |

288 rub |

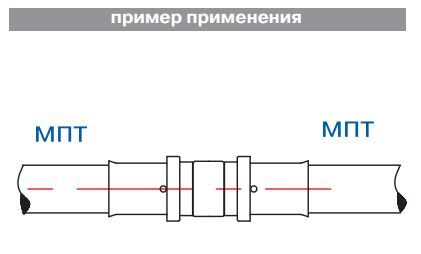

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 60 |

20 |

20 |

0,072 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 26х16 [Code number: VTm.203.N.002616]

Details

|

VTm.203.N.002616 |

411 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 61 |

26 |

16 |

0,086 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 26х20 [Code number: VTm.203.N.002620]

Details

|

VTm.203.N.002620 |

423 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 61 |

26 |

20 |

0,092 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 26 [Code number: VTm.203.N.002626]

Details

|

VTm.203.N.002626 |

445 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 62 |

26 |

26 |

0,106 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 32х16 [Code number: VTm.203.N.003216]

Details

|

VTm.203.N.003216 |

522 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 62 |

32 |

16 |

0,132 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 32х20 [Code number: VTm.203.N.003220]

Details

|

VTm.203.N.003220 |

690 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 62 |

32 |

20 |

0,137 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 32х26 [Code number: VTm.203.N.003226]

Details

|

VTm.203.N.003226 |

644 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 63 |

32 |

26 |

0,151 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 32 [Code number: VTm.203.N.003232]

Details

|

VTm.203.N.003232 |

610 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 63 |

32 |

32 |

0,144 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC Coupling, d - 40 [Code number: VTm.203.N.004040]

Details

|

VTm.203.N.004040 |

1 206 rub |

Application purpose:

- For metal-polymer and polymer pipes

- To create permanent connections

- For connecting a polypropylene pipeline and an engineering system component with a threaded connection at an angle of 90° to each other

Characteristics:

- Pressing tool attachment type - TH (according to the REMS catalog)

- Thread type on adapter connectors - pipe thread, according to GOST 6357-81, accuracy class "B"

- The material of the press fitting body is made of hot-stamped (GOSH) nickel-plated brass of the CW617N brand according to EN 12165 (corresponds to the LS 59-2 brand according to GOST 15527-2004)

- Press sleeve made of stainless steel AISI 304 (corresponds to grade 08X18H9 in accordance with GOST 5632-2014)

- O-rings made of EPDM

- Nominal pressure 2.5 MPa

- Working pressure 1.0 MPa

- Maximum temperature of the working environment +115 ºС

- Minimum storage temperature -30 ºС

- Emergency working environment temperature +130 ºС

- Sleeve compression force, not less than 1200 N

- Average full service life 50 years

Allowable pipe parameters:

| Outer pipe diameter, mm |

16 |

20 |

26 |

32 |

40 |

| |

|

|

|

|

|

| Pipe wall thickness, mm |

2,0 |

2,0 |

3,0 |

3,0 |

3,5 |

| Aluminum thickness (no more), mm |

0,4 |

0,5 |

0,5 |

0,5 |

0,5 |

| Swaging zone diameter, mm |

16,7 |

20,7 |

26,7 |

32,7 |

40,8 |

| А |

D1 |

D2 |

Weight |

| mm |

mm |

mm |

kg/pc |

| 79 |

40 |

40 |

0,295 |

Download data sheet:  Connecting parts for VALTEC pressfitting Connecting parts for VALTEC pressfitting

|

|

|

VALTEC PPR Detachable coupling, d - 20 [Code number: VTp.763.0.020]

Details

|

VTp.763.0.020 |

284 rub |

Application purpose:

- For cold and hot water systems

- For heating

- To create a union using a union nut

Characteristics:

- Nickel-plated brass union nut

- Nominal pressure up to 25 bar

- The maximum temperature of a working environment is up to +95 ºС

- Minimum storage temperature up to -30 ºС

- Mounted by socket welding

- O-ring made of synthetic rubber EPDM

| d |

A |

B |

Weight |

| mm |

mm |

mm |

kg/pc |

| 20 |

42 |

39 |

0,079 |

Download data sheet:  Fittings for VALTEC PPR Fittings for VALTEC PPR

|

|

|

VALTEC PPR Detachable coupling, d - 25 [Code number: VTp.763.0.025]

Details

|

VTp.763.0.025 |

506 rub |

Application purpose:

- For cold and hot water systems

- For heating

- To create a union using a union nut

Characteristics:

- Nickel-plated brass union nut

- Nominal pressure up to 25 bar

- The maximum temperature of a working environment is up to +95 ºС

- Minimum storage temperature up to -30 ºС

- Mounted by socket welding

- O-ring made of synthetic rubber EPDM

| d |

A |

B |

Weight |

| mm |

mm |

mm |

kg/pc |

| 25 |

45 |

42 |

0,137 |

Download data sheet:  Fittings for VALTEC PPR Fittings for VALTEC PPR

|

|

|

VALTEC PPR Detachable coupling, d - 32 [Code number: VTp.763.0.032]

Details

|

VTp.763.0.032 |

660 rub |

Application purpose:

- For cold and hot water systems

- For heating

- To create a union using a union nut

Characteristics:

- Nickel-plated brass union nut

- Nominal pressure up to 25 bar

- The maximum temperature of a working environment is up to +95 ºС

- Minimum storage temperature up to -30 ºС

- Mounted by socket welding

- O-ring made of synthetic rubber EPDM

| d |

A |

B |

Weight |

| mm |

mm |

mm |

kg/pc |

| 32 |

53 |

51 |

0,172 |

Download data sheet:  Fittings for VALTEC PPR Fittings for VALTEC PPR

|

|

|

VALTEC PPR Detachable coupling, d - 40 [Code number: VTp.763.0.040]

Details

|

VTp.763.0.040 |

1 256 rub |

Application purpose:

- For cold and hot water systems

- For heating

- To create a union using a union nut

Characteristics:

- Nickel-plated brass union nut

- Nominal pressure up to 25 bar

- The maximum temperature of a working environment is up to +95 ºС

- Minimum storage temperature up to -30 ºС

- Mounted by socket welding

- O-ring made of synthetic rubber EPDM

| d |

A |

B |

Weight |

| mm |

mm |

mm |

kg/pc |

| 40 |

62 |

59 |

0,336 |

Download data sheet:  Fittings for VALTEC PPR Fittings for VALTEC PPR

|

|

|

VALTEC PPR Detachable coupling, d - 50 [Code number: VTp.763.0.050]

Details

|

VTp.763.0.050 |

2 223 rub |

Application purpose:

- For cold and hot water systems

- For heating

- To create a union using a union nut

Characteristics:

- Nickel-plated brass union nut

- Nominal pressure up to 25 bar

- The maximum temperature of a working environment is up to +95 ºС

- Minimum storage temperature up to -30 ºС

- Mounted by socket welding

- O-ring made of synthetic rubber EPDM

| d |

A |

B |

Weight |

| mm |

mm |

mm |

kg/pc |

| 50 |

70 |

72 |

0,587 |

Download data sheet:  Fittings for VALTEC PPR Fittings for VALTEC PPR

|