No hub sewer pipes system earned faith and consumers' estimation during the years of existence. Tubes and fittings PAM-GLOBAL® possess a number of advantages:

|

|

|

|

| New internal covering of pipes with rationalized section HPS 2000 | The best protection against corrosion of fittings with cataphoresis covering - KTL (in and out) | Strictly compatible fitting systems in the very highest quality | Insulation, low-noise drain according to DIN 4109 (and VDI 4100) |

|

|

|

|

| Preventive fire protection, pipes and fittings PAM-GLOBAL® do not burn, in accordance with DIN 4102 | Insensible to heat and cold, low thermal expansion coefficient (0.0105 mm / mk), almost like concrete has. Thereby there is a possibility of unproblematic concreting | High resistance considerably exceeding the requirements of DIN EN 877 | High durability, guarantee an optimal flow due to the smooth surface |

|

|

|

|

| Stable and retain the shape, shock-resistant | Factory priming, long-lasting good appearance, due to a special factory outer covering (e.g.,bridges building) | 100% recycling, no problems with disposal | There is no waste of resources, pipes PAM-GLOBAL to 95% consist of recycled metal |

| Standard DIN EN877 | PAM-GLOBAL® products | |

|---|---|---|

| Specific weight | ~ 7,2 kg/dm3 (71,5 kN/m3) | +++ |

| Breaking strength of fittings | ≧150 MPa | ≧300 MPa |

| Breaking strength of pipes | min 200 MPa | 300 MPa |

| Compression strength | approx. 3 to 4 times the value of the breaking strength | 450 MPa |

| Shear resistance | 1,1 to 1,6 times the value of the breaking strength | +++ |

| Ring crush strength | ≧350 MPa | +++ |

| Elastic modulus | from 8×104 to 12×104 N/mm2 | +++ |

| Poisson's ratio | -(0,3) | +++ |

| Thermal conductivity | 50-60 (for 20ºC) W/(m·K) | +++ |

| Thermal stability | without causing significant changes of mechanical properties: up to 400 ºC | melting point 1000 ºC |

| Thermal expansion | only 0.0105 m/mK (in the range from 0ºC to 100ºC), like concrete; possible trouble-free installation into the concrete | 0.0105 m/mK |

| Surface roughness | 1. K0 = 0,25 mm for HDE-EPAMS VDI3806 2. Normal risers for buildings without considering the U-resistance K0 - 1,0 mm (DIN 1986, EN 12056) |

+++ |

| Brinnel surface hardness | max. 260 НВ | 220 HB |

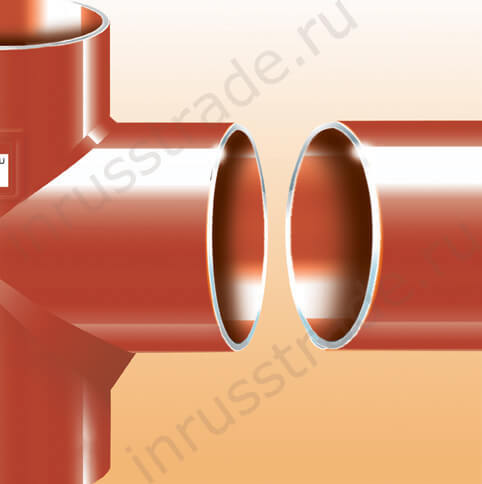

Method of centrifugal casting DeLavaud

| Infusion into cold form and further quick cooling |

| Internal structure: graphite rosette shape |

| Internal structure is similar to Ductile Ironre |

One of decisive advantages of the method DeLavaud: PAM-GLOBAL® pipes are put in a heating furnace after casting, and pipes are stood in the heating furnace for some time at 950ºC. Then pipes are cooled quickly. This heat treatment of pipes leads to transformation of cast iron microstructure: procedure reduces iron carbides and increases ferrite content. It leads to improvement mechanical properties of cast iron, lowering cast iron surface hardness and increasing tensile strength. Graphite cast iron takes a very small rosette shape at low tide the pipes by the method of De Lavaux.

Cast Iron has many pluses. It is known that the cast iron preserves mechanical properties for a long time which prolongs its service life. That is, the cast iron has high resistance to aging.

Also this material does not deform under mechanical strain. Longitudinal stiffness of cast iron remains intact. Its Young modulus of elasticity is ranking from 80 to 120 GPa, while the PVC Young modulus of elasticity is 2 to 5 GPa. Cast iron's tensile strength is about 8 times greater than that of PVC - 200 MPa vs 25 MPa. This property is the most importance in case of network overloading.

Ring stiffness of cast iron is about 700 kN*m, that is 87 times greater than that of PVC, and the ring stiffness of cast iron pipes is independent of temperature.

Also cast iron undergoes no structure modification under climatic stresses (ultraviolet light etc.).

Another advantage the PAM-GLOBAL® pipes is the special coating. The SAINT-GOBAIN Company analyzes the coatings of all products often and improves it that would provide better protection against corrosion and increase durability of the pipes and fittings.

The inner coating of the PAM-GLOBAL® pipes was withstanded the maximum amount of chemical influences and it had high abrasion resistance. The inner coating was made of polymers which are analyzed constantly, and it provides high bandwidth and preventes formation of plaque and deposits. Average thickness of the epoxy coating is 130 microns for PAM-GLOBAL® S system and 250 microns for PAM-GLOBAL® PLUS system..

The external coating of the pipes is covered acrylic paint 40 μm. Fittings are covered epoxy foil red-brown color by electrophoresis and thermo-seating.

The external coating of PAM-GLOBAL pipes is characteruzed by high protection against corrosion, because it is zinc metallization (130 g/m2). The zinc metallization not only form an insoluble protective layer, but also adds the function of self-healing of any damage. So that the zinc metallization is not just a way to protect the pipe against corrosion, also it extends service life of cast-iron pipes.

The SAINT-GOBAIN Company achieves maximum resistance of the pipes and fittings to aggressive environments (see. table). In addition, specially designed the inner coating and the external coating of the PAM-GLOBAL pipes and fittings provide better protection against corrosion for a long time.

The drainage system belongs to the A1 Class for Bulding Material according to DIN 4102 in Germany and is non combustible. It is CE marked on EN 877, and after tests in a third party accredited laboratory, is ranking "A2-s1,d0", for the complete system.

The manufacturing plant is certified ISO 14001.